Everyone knows that to improve production capacity and reduce lead time you first need to cut waste and boost performance efficiency. But where to begin? The first step is to measure every activity on the production line. This is job number one for Leela Visual Intelligence Platform.

Manufacturers are increasingly adopting sensor-driven IIoT analytics to measure productivity. Yet while IIoT is great at revealing equipment status and throughput, it misses the human-driven activity that occurs between the machines. Traditionally, frontline worker activity has been measured using time and motion studies. Yet, T&M studies are prone to human error and bias, and in frequently changing operations, they must be repeated at considerable expense.

Harnessing the power of AI-driven visual intelligence, Leela Platform is like a continuous, unbiased time and motion study. Like T&M, the software fills in the data that IIoT misses, but it does so consistently over time at a much lower cost.

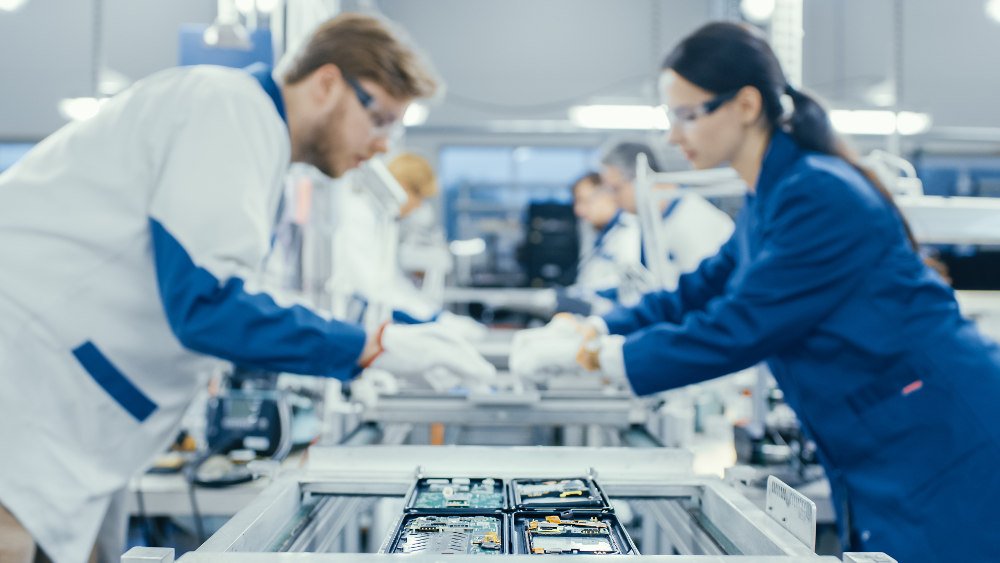

Our manufacturing monitoring system measures and analyzes complex interactions between people, tools, machinery, robots, parts, and products. The software identifies and times every step in the production process, and displays the metrics using intuitive graphics in the Leela Viewer KPI dashboard. Privacy controls include face and body blurring and the option to disable video storage.

Leela Platform metrics include cycle time, throughput, and value vs. non-value add time. Our manufacturing analytics software can track the average number of workers on a given task, as well as time spent standing, sitting, walking, carrying, welding, cutting, or operating a machine.

When deployed with our new Advanced Performance Module, Leela also tracks performance (units completed/person-hour). By visually counting the number of pieces completed per hour and factoring in labor deployment, unplanned downtime, and changeovers, the module can do what no smart manufacturing solution has achieved before: tracking the allocation of time and the completion of production units at every workstation.

Leela Platform can also backstop IIoT analytics of equipment performance with a second opinion. For example, our software can read HMI screens and gauges and flag visible clues such as chokepoints, clogs, leaks, smoke, and explosions. This is especially useful for monitoring legacy equipment that lacks sensors.

Leela Platform integrates data from multiple cameras to create a unified, bird’s eye analysis that can be used to compare shifts and stations and identify bottlenecks and best practices. Leela generates a detailed value stream map that you can use to identify opportunities for improving capacity and reducing waste, especially wasted labor.

With Leela, you can easily ask and answer complex questions and test hypotheses. For example, one of our customers wanted to know when, why, and for how long frontline employees were leaving the assembly area. The resulting analytics led them to move the parts bins closer to improve productivity.

By sharing Leela’s dashboard from the front office to the front line, everyone in the organization can improve their operational visibility and focus on common goals. The entire workforce can help steer a path toward accomplishing more every shift.