Before you can reduce lead time in manufacturing, you must improve manufacturing production capacity. The first step is to measure all the activities that contribute to it. You cannot improve what you cannot measure.

For decades, the most common productivity measuring tool has been the time and motion study. Yet, in frequently changing operations, the studies must be repeated at considerable expense.

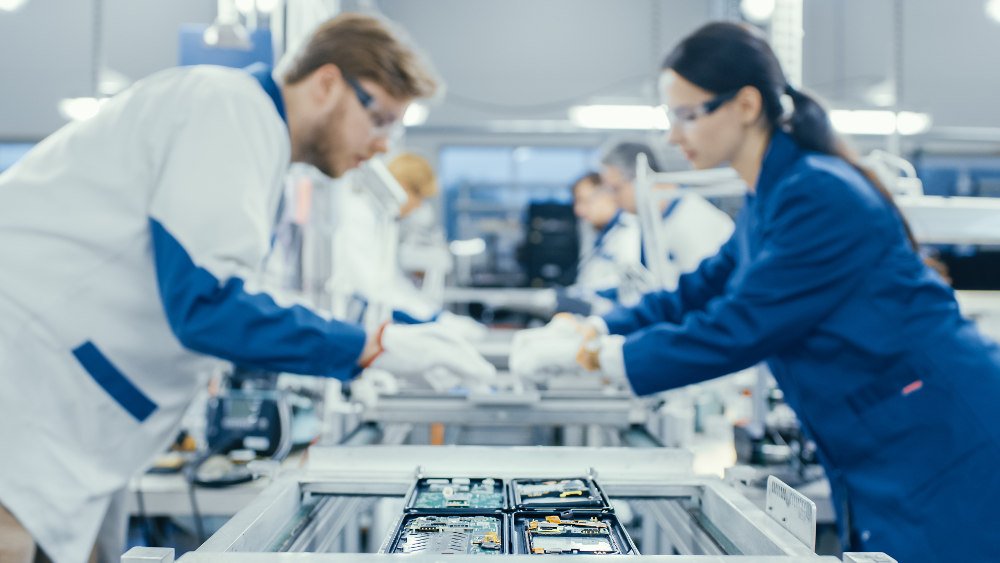

More recently, manufacturers have adopted sensor-driven IIoT analytics. While IIoT improves understanding of equipment status and throughput, it misses the human-driven activity that occurs between the machines.

Metrics include cycle time, throughput, value vs. non-value add time, and in our most recent release, productivity (units completed/person-hour). The manufacturing analytics software can track the average number of workers on a given task, as well as time spent standing, sitting, walking, carrying, operating a machine, welding, or cutting.

Leela also acts as a machine monitoring dashboard that can backstop IIoT analytics with a second opinion. For example, our manufacturing intelligence software can read HMI screens and gauges and flag visible clues such as chokepoints, clogs, leaks, smoke, and explosions.

Leela Platform can integrate data from multiple cameras to create a unified, bird’s eye analysis that can be used to compare shifts and production stations and identify bottlenecks and best practices. Privacy controls include face and body blurring and the option to disable video review and storage.

Our reports combine to create a detailed value stream map that you can use to identify opportunities for improving processes to increase production capacity and reduce manufacturing lead time. Once you make a change, you can measure how it improves productivity and reduces waste, especially wasted labor.

With Leela, you can easily ask and answer complex questions. For example, one of our customers wanted to know when, why, and for how long frontline workers were leaving the assembly area. The resulting analytics helped them determine a way to improve productivity by moving the parts bins closer to the assembly area.

Increasing capacity usually requires changing the culture to encourage teamwork. By sharing analytics from the front office to the front line, Leela Platform enables everyone to focus on a common point of reference. In this way, the entire workforce can improve their operational visibility to confirm or reject hypotheses and steer a path toward continuous improvement.