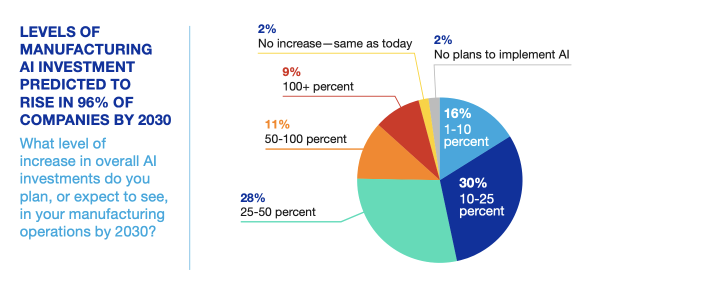

The Manufacturing Leadership Council, sponsored by the National Association of Manufacturers (NAM), has posted the results of a survey as part of its Manufacturing in 2030 Project. The survey reports that by 2030 almost half of responding US manufacturers expect to increase their AI investments by between 25% and 100%. Only 2% have no plans to invest in AI. Yet, there are concerns that data handling challenges, lack of AI expertise, and lack of metrics for evaluating AI benefits could slow the rollout.

Leading AI applications include plant floor IoT analysis (40%), preventative maintenance (36%), and process and quality improvement, both at 30%. Expected benefits from AI investments are led by better decision making and are followed closely by cost savings, better planning, increased competitive advantage, and increased sustainability, among others.

Below are selected charts from The Future of Industrial AI in Manufacturing 2023 report plus additional findings in bullet points farther below.

Other findings:

- 29% say their company has a formal corporate plan and strategy for AI; 43% say individual units and divisions are devising their own AI plans.

- 51% have a moderate level of confidence in their company’s internal AI expertise; only 8% have a high level.

- 34% of respondents say the head of manufacturing is in charge of AI efforts; 21% say the head of corporate IT; 10% say the chief digital officer or chief data analytics officer.

- 22% say their company has specific metrics in place to measure AI effectiveness; 61% say there are no metrics.