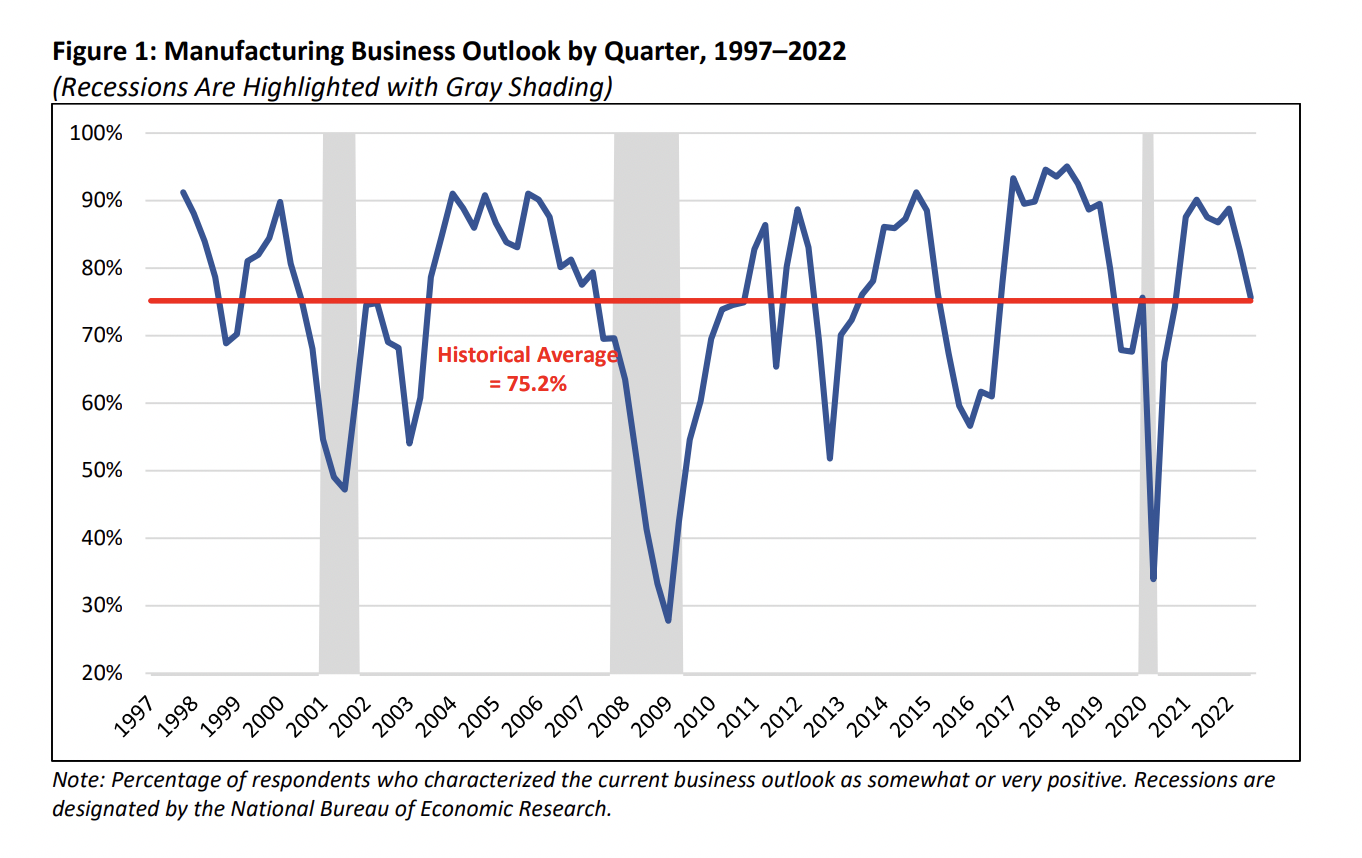

While US manufacturers can take cheer in the 3Q decline in Covid cases, some problems just refuse to go away. The recent release of the National Association of Manufacturers Q3 2022 Manufacturers’ Outlook Survey reveals that US manufacturers list supply chain disruptions (78.3%), difficulties in attracting and retaining a quality workforce (76.1%) and increased raw material costs (76.1%) as the leading business concerns. The report, based on an August 2022 survey, indicates that few manufacturers believe any of these problems will disappear soon. Only 75.6% had a positive outlook about their company’s near-term prospects, the lowest since Q4 2020.

Leela’s take: The next few quarters are likely to be tough sledding, but we are optimistic about the prospects for long-term growth. There is now widespread consensus that a strong domestic manufacturing industry is essential to the country’s future success. Meanwhile, many manufacturers will benefit from recent government investments in clean energy and semiconductor manufacturing. And as noted by the NAM report, US manufacturers have shown surprising resilience in bouncing back from the pandemic and the worst of the supply chain slowdowns.

https://bit.ly/source-pdf

The other good news is that there are many new technological solutions aimed at manufacturing, and some are particularly relevant to our current challenges. For example, video intelligence software such as Leela Platform is designed to help teams increase their productivity without adding more people. As we saw in our debut September blog post, always-on video analytics make it easier to quickly adjust operations to respond to sudden labor and supply shortages. AI-enabled software such as Leela can identify bottlenecks and highlight best practices to boost productivity, driven by accurate real-time data. The goal is that everyone in the operation from the front-line worker to the executive suite can learn from the analytics and enable continuous improvement.

As we explored in this week’s blog entry, video intelligence is designed to identify process defects just as other machine learning software can spot product defects. Process detection can have a similar impact on reducing material waste by generating more usable products that won’t be returned. In times of high material costs, this extra edge can be significant. As we saw in one customer example, Leela Platform can also indirectly perform product inspection, identifying a slowdown that was caused by a faulty part.

Leela can communicate with existing manufacturing software solutions without requiring that customers overhaul them. We help you install the cameras and set up and tune the software to your preferences. Within a few weeks, Leela will be generating graphs and statistics that highlight the highs and lows of your operation and point to potential solutions. The rest is up to you.

Video intelligence can’t solve all the problems faced by manufacturers. Yet, it can give them a fighting chance by making their operations more visible.