Cyrus Shaoul CEO, Leela AI

Over the last two years I have visited dozens of manufacturing operations in North America, Europe, and Asia, checking in with customers and searching for new opportunities where the Leela Video Intelligence Platform can help boost productivity. Every manufacturer I speak with mentions one overarching challenge: the ongoing labor shortage. This is especially true in the US where there are many high touch operations that cannot be easily automated. The human is firmly in the loop, and despite improvements to robotics, will be there for some time.

The same goes for labor shortages, which are likely to persist in manufacturing longer than in other lines of work that have been disrupted by the pandemic. Improvements in automation and investments in industrial education will help, as will increases in wages, which have ticked up slightly in 2022. Yet, with baby boomers retiring in droves and desktop jobs gaining appeal due to work-at-home policies that are impossible to implement on the factory floor, manufacturers will be living with shortages for years. According to a 2021 Deloitte study, US manufacturers are expected to have 2.1 million unfilled jobs by 2030.

Some manufacturers try to fill the labor gap by asking employees to work faster. Yet this often leads to more product defects, on-the-job accidents, poor morale, and job burnout. High job turnover means more time and money spent hiring and training, and more gaps to fill.

Today’s labor shortages have been made more challenging by the Covid-19 pandemic, which in the early days led to work stoppages and continues to result in high absenteeism. On top of this, material shortages resulting from supply chain disruptions have further conspired to play havoc with manufacturing operations.

Although some of these problems are beginning to fade, pandemics are expected to become more frequent along with extreme weather events that can lead to prolonged outages and stoppages. Meanwhile, accelerating technological change in the factory, from robotics to the Internet of Things, adds to the disruptions while requiring more training time.

The good news is that your competitors are facing the same challenges. Yet, you may have noticed that some of them have a new tool that you don’t: video intelligence. Using the power of deep learning algorithms combined with low-cost cameras, video analytics platforms such as the Leela Platform are increasing manufacturers’ visibility and insights into operations and providing a valuable tool to deal with shortages and uncertainty.

Improving visibility into operations

Even if you have been watching your factory floor for years, it is impossible in all but the smallest operations to fully grasp what is going on at every station, not to mention the complex interactions between them. Time and motion studies can help, but they are also expensive and susceptible to the biases and oversights of individual analysts.

Another problem with time and motion analyses is that they capture only a snapshot in time. Manufacturing operations with frequent changes to operations need to repeat the studies at considerable cost.

Frequent process changes are becoming the norm in many manufacturing operations. In addition to adjustments needed to address fluctuating staffing, supply shortages, and technological overhauls, the pace of change is being accelerated by trends in product design. There are more products, more variations and options within each product, and faster evolution in product designs than ever before. A month from now your assembly line may look considerably different than it does now.

Simple sensor-based analytics systems based on standard IoT technology offer another alternative for identifying inefficiencies in production. Unlike time and motion studies, they are always on so they provide analytics over time. Sensors can provide valuable insights for highly automated operations. Yet in high touch manufacturing with a lot of humans in the loop, they miss much of the action.

Due to the limitations of the alternatives, the industry is steadily moving toward video analytics. Unlike earlier productivity evaluation solutions, video analytics is always on, sensing and measuring operations 24-7. Yet many of these solutions have a reputation for being complex, data hungry, and slow to train – and retrain when operations adapt.

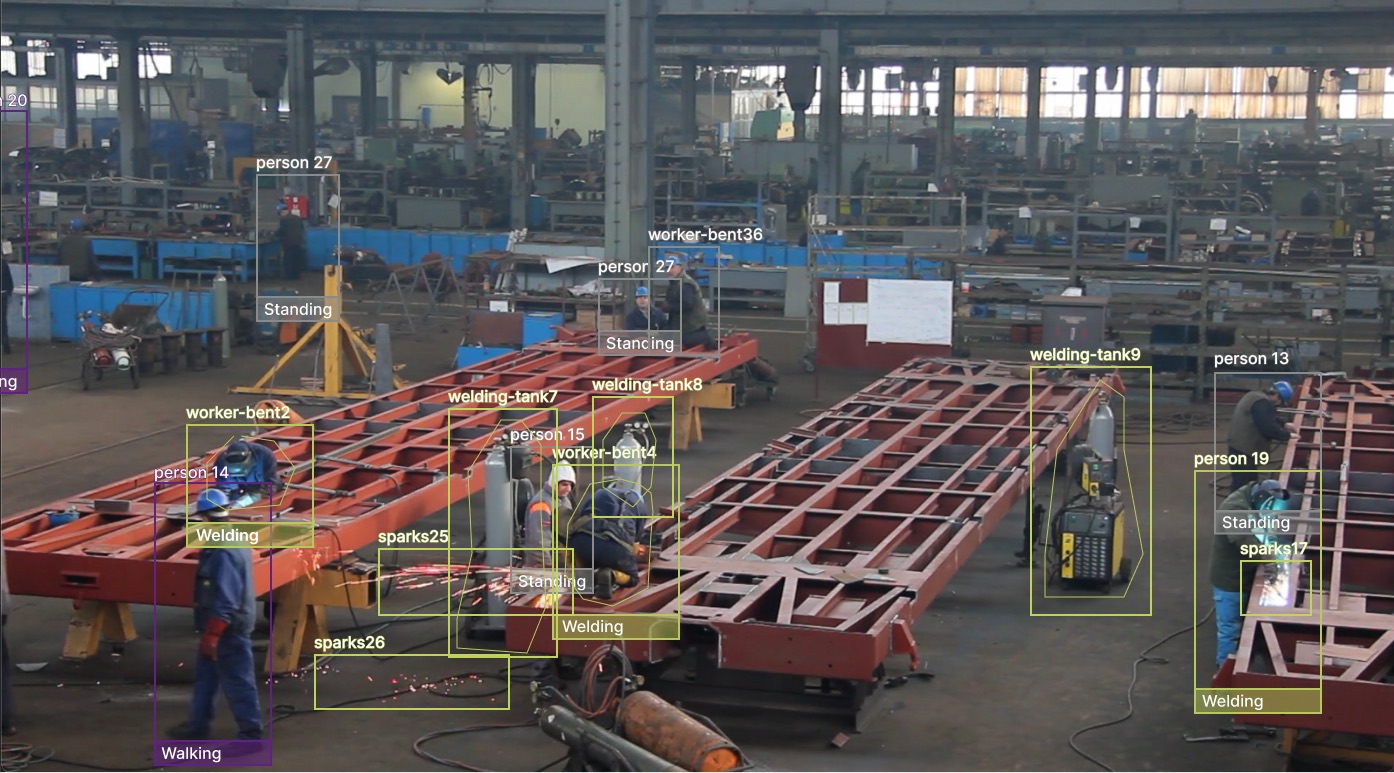

The Leela Platform is among a new wave of AI-enhanced video intelligence systems that overcome these shortcomings. Video intelligence platforms can analyze individual steps at a high level of granularity. They excel at analyzing the big picture, including interaction between different stations and multi-stage manufacturing processes.

The best video intelligence systems can more easily identify bottlenecks, as well as work that is done too fast or too slow. The Leela Platform, for example, can easily tell the difference between non value-added time, such as operators waiting around for another team to finish a foundational part, and value-added time when they are applying tools to a product. The software not only spots problems, but can identify best practices so they can be taught to other workers.

With platforms such as Leela, employees from the front-line operator to the CEO can view real-time metrics at any time and see how current operations compare against the historical record. They can also compare efficiency between shifts and locations.

Another advantage of video intelligence platforms is that they are less intrusive than hands-on time and motion studies. Many factories already have security cameras installed, and like Leela, most of the platforms offer facial and body blurring to ensure privacy.

Like other new digital manufacturing technologies, video intelligence platforms require an investment of time and money. With solutions such as Leela, however, the financial investment is spread over time through a subscription package. If it’s not working for you, you can easily back away without significant changes to your operation beyond, perhaps, the purchase of a few cameras. This model makes it easy to test out the system on a high-value problem without needing to invest in expensive infrastructure.

One major advantage offered by Leela is that AI training time is drastically reduced, so you can start to see value from the analytics 10 times faster and with 100 times less data than with typical video analytics solutions. The key is Leela’s unique hybrid causal/neural network technology, which differs from the traditional neural network architectures used by other solutions.

The causal side of the hybrid network enables the AI to understand work at the level of concepts and context rather than simply matching specific patterns. The combination enables greater analytical insights than is possible with neural network-only solutions, letting you quickly train the system to reflect continual changes in labor, supplies, and product designs.

In future posts, I will drill more deeply into the Leela Platform and show how it can help boost productivity and solve many of the thorniest problems faced by today’s manufacturers. Meanwhile, you can follow us on LinkedIn to find out about upcoming webinars or contact us for a demo or consultation.